Applications Where Electrostatic Ultrasonic Sensors Outperform Piezoelectric Sensors

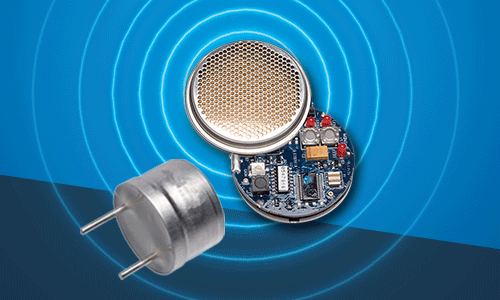

Electrostatic ultrasonic sensors and transducers deliver performance advantages that piezoelectric sensors cannot match—particularly in applications that require long range, soft-target detection, small-object recognition, or stable operation across temperature changes. By leveraging a lightweight electrostatic membrane rather than a heavy ceramic disk, these sensors achieve up to 40 dB higher sensitivity, and maintain consistent performance in conditions […]

Applications Where Electrostatic Ultrasonic Sensors Outperform Piezoelectric Sensors Read Post »