When most engineers think about in-air ultrasonic sensing, they picture a cheap, ceramic “hockey puck” — a piezoelectric transducer. But piezo is not the only option, and not always the right choice.

Electrostatic ultrasonic sensors use a different transduction mechanism that delivers higher sensitivity, wider bandwidth, and more stable performance in demanding in-air applications.

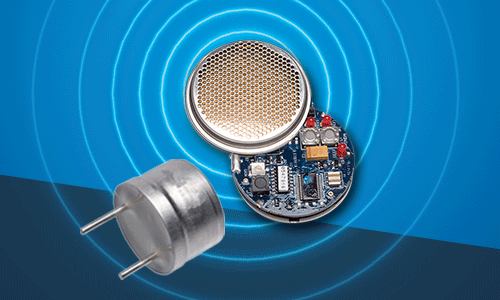

How do Electrostatic Ultrasonic Sensors Work?

Electrostatic ultrasonic sensors operate more like a capacitive microphonethan a resonant ceramic element. Electrostatic transducers use:

- A fixed backplate with concentric grooves that shape the ultrasonic beam.

- A thin dielectric film coated with a thin gold layer on one side, stretched over the backplate like a drumhead.

- A DC bias plus an AC drive signal between the film and backplate.

When a 50 kHz drive waveform is applied, the biased film is electrostatically attracted and released, displacing air and generating an ultrasonic pulse. On receive, motion of the film caused by incoming ultrasound modulates capacitance and produces a small AC current that the receiver electronics amplify and process.

Because the device is fundamentally capacitive and non-resonant, its behavior is quite different from a piezo disc.

How do Piezo Ultrasonic Sensors Work?

Piezoelectric ultrasonic sensors are built around a ceramic element, typically lead zirconate titanate (PZT), sandwiched between electrodes. When you apply a high-frequency AC voltage, the ceramic expands and contracts (inverse piezoelectric effect), generating ultrasonic vibrations. When incoming ultrasound flexes the ceramic, it generates a voltage (direct piezoelectric effect).

Key characteristics of piezo ultrasonic transducers:

- Resonant devices — designed to operate near a single resonant frequency (often ~40 kHz for in-air range finding).

- Narrower bandwidth and longer ring-down, which can limit minimum detection distance and flexibility across frequencies.

- Frequency drift with temperature, requiring circuit techniques (impulse drive, wide bandpass filters) to maintain performance over broad temperature ranges.

Electrostatic vs. Piezo Ultrasonic Sensors

1. Which Sensor Technology Gives You Better Distance, Sensitivity, and Soft-Target Performance?

- Electrostatic

- Typically ~40 dB higher sensitivity than comparable piezo devices.

- Practical ranging from 1 inch to over 40 feet in air with a single transducer and appropriate driver/receiver circuitry.

- Can detect very small or low-reflectivity targets (e.g., a pencil at 10 ft).

- Piezo

- Lower receive sensitivity in air; long-range performance requires higher-gain, lower-noise electronics and careful transducer design.

- Typical in-air piezo pairs cover distances from just a few inches out to tens of feet, but long range often trades off against minimum blind zone and beam pattern.

Takeaway: If you need long range and reliable detection of small or soft targets in air, electrostatic ultrasonic is a strong choice.

2. How Sensor Bandwidth and Ring-Down Affect Close-Range Performance

- Electrostatic

- Broadband response: optimized around 50 kHz and usable from roughly 40–100 kHz.

- Non-resonant, with very low ring-out, allowing very short transmit pulses and minimal blind zone.

- Piezo

- Narrowband, resonant devices—excellent efficiency near the design frequency, but limited bandwidth.

- Significant ring-down after the transmit pulse; designers often must use separate transmit/receive transducers to reduce the dead zone for close-range detection.

Takeaway: For applications where you need to measure close to the sensor, pulse quickly, or operate across multiple frequencies, electrostatics minimize blind spots and improve precision.

3. How to Maintain Sensor Performance Across Wide Temperature Swings

- Electrostatic

- Performance is very stable across a wide range, typically –40°C to +125°C, with minimal frequency or gain drift.

- This stability allows simpler drive and receive circuits that don’t require complex temperature compensation.

- Piezo

- Resonant frequency and impedance drift with temperature, which can impact range and sensitivity unless compensated by additional circuit design (e.g., impulse drive and wideband filters).

- Resonant frequency and impedance drift with temperature, which can impact range and sensitivity unless compensated by additional circuit design (e.g., impulse drive and wideband filters).

Takeaway: If you use sensors outdoors or in wide-temperature industrial settings, electrostatic devices simplify your design by offering stable, predictable behavior.

4. Which Sensor Technology Gives You Reliable Echoes From Difficult Targets?

- Electrostatic

- High sensitivity and broadband operation make them excellent at detecting soft, acoustically absorbent targets like people, produce, foliage, and irregular surfaces.

- Can reliably detect very small cross-section targets (e.g., small tools, narrow edges, pencils) at meaningful distances.

- Piezo

- Work well on hard, smooth targets, but may struggle with soft or highly absorbent surfaces at longer range without careful design and gain.

Takeaway: If you need to detect irregular, absorbent, or very small objects, electrostatic sensors provide cleaner, more reliable echoes than piezo devices.

5. Which Sensor Technology Makes Design, Power, and Integration Easier?

- Electrostatic

- Electrostatic sensors can operate at low power—well under 0.15 W—while still delivering long range and high sensitivity.

- Capacitive structure and stable behavior make it straightforward to integrate compact sensor modules, including drive/receive electronics in the same housing.

- Piezo

- Typically, efficient around their resonance but achieving long range in air often requires higher drive voltages and complex gain profiles.

Takeaway: If your job requires low power consumption, simplified electronics, or compact integration, electrostatic sensors reduce design overhead and enable smaller, more efficient systems.

6. Choose a Sensor That Matches Your Environment

Both technologies are designed for non-contact sensing, but their environmental sweet spots differ:

- Electrostatic

- Best suited for in-air applications.

- Not suitable for underwater applications and will stop working when wet, although they generally recover once dried.

- Piezo

- Can be designed for air, liquid, or solid media, including underwater sonar and industrial ultrasonics, using appropriate matching layers and housings.

Takeaway: For in-air non-contact sensing, electrostatics shine. For underwater or immersion applications, piezo is the standard choice.

When is an Electrostatic Ultrasonic Sensor the right choice?

If your in-air application has any of these requirements:

- Requires long range with minimal blind zone

- Must reliably detect soft, small, or difficult targets

- Operates across wide temperature ranges

- Needs clean echoes and flexible signal processing

then electrostatic ultrasonic sensors can deliver superior performance to conventional piezo solutions, often with simpler electronics and lower overall system risk.